Startup to Sale: How Cohort 2015 Fellow Tom McDonald Built and Sustained Mosaic Materials

May 10, 2022

Baker Hughes has acquired the startup and plans to deploy its carbon dioxide capture technology across the industrial value chain.

Tom McDonald was going to be a professor. That was the plan. He even had a postdoc lined up at Imperial College London and had told his landlord he was moving to Europe. But then Jeff Long, the UC Berkeley professor under whom he was wrapping up his Ph.D., and Steven Kaye, who had also studied under Long, convinced McDonald to give the startup route a shot. So McDonald decided to join Long and Kaye as a co-founder of Mosaic Materials.

%201.png)

Cohort 2015 fellow and Mosaic Materials co-founder Tom McDonald

Fast forward seven years: Mosaic Materials has refined a new, powerful, low-energy approach to carbon dioxide capture, both from stationary sources and carbon dioxide removal (CDR) from the atmosphere and Houston-based Baker Hughes has acquired the startup in order to further develop and scale the technology.

We created the Activate Fellowship to allow scientists and engineers who are interested in turning their research into a product to answer the question: what if? McDonald could not have pursued the answer had he stayed in academia, but the fellowship—he was part of Cohort 2015—afforded him the time and resources to dive in.

“I considered it long and hard—it was a really close decision between Mosaic and academia. I ended up saying, ‘Well if I don't do this, the technology is gonna die. So yes, I'll do it,” he says.

A Material Issue

While pursuing his undergrad degree at Northwestern, McDonald became curious about porous materials, especially those useful for energy applications. When he started graduate work at UC Berkeley under Jeff Long, he followed that curiosity and joined a research group that was part of the Center for Gas Separations. One of the Department of Energy’s Energy Frontier Research Centers, the center was exploring how metal-organic frameworks, or MOFs, could be used to make gas separations more energy efficient and affordable.

Tom McDonald (Cohort 2015) presenting Mosaic’s innovation.

“I had wanted to work on climate ever since reading Al Gore's book when I was in eighth grade,” says McDonald. “So I said ‘sign me up.’ It was only my third day of grad school and I already knew I would be working on carbon capture using MOFs and I basically did that for the next 13 years.”

McDonald and his fellow researchers spent a few years experimenting with adding amine compounds to MOFs, because amines “give you really great selectivity, capacity, and tolerance from water which were some really critical criteria,” he explains. This was an unusual and controversial approach, however, because it was assumed that removing large quantities of CO2 captured with Mosaic’s amine-functionalized MOFs would require a large amount of energy, relative to other MOFs. But the Mosaic team showed that was not the case.

Plus, in the course of his research, he invented a sorbent that displayed unusual CO2 absorption properties, including the ability to pull CO2 directly out of the air. “This was the first example of a MOF that had been observed as being usable for direct air capture,” he says.

Mosaic Material’s core focus was to further develop and commercialize that invention.

“I considered it long and hard—it was a really close decision between Mosaic and academia. I ended up saying, ‘Well if I don’t do this, the technology is gonna die. So yes, I’ll do it. ”

“It’s been such a pleasure and an honor to support Tom and Mosaic over the past six years,” says Activate CEO Ilan Gur. “Tom’s personal focus on driving climate impact is inspiring. He and his co-founders were intent on proving that MOFs were more than fanciful academic chemistry but could be powerful tools for carbon capture. The Baker Hughes acquisition is a great step forward for the company and for meeting the urgent need for effective carbon removal technology across industries.”

Government Funding

When McDonald joined Activate, Mosaic had developed a really great material for carbon capture. But back in 2015, very few investors were interested in funding the technology.

So McDonald looked to government grants and partners for support in those early days, as it de-risked the technology and started to work on the cost curve.

“I think so much of the story of Mosaic has been just being helped along the way by a lot of really amazing government sponsors,” he says. The first of these was the California Energy Commission, which funded Mosaic to investigate using the MOFs Mosaic was developing to drive down the cost of biogas production.

“That was really a critical lifeline—along with the Activate Fellowship—during that period,” McDonald recalls.

The U.S. Navy and NASA were other important government sponsors. Each took an interest in how Mosaic’s materials could improve CO2 removal for life support within submarines and spacecraft, respectively.

“I think so much of the story of Mosaic has been just being helped along the way by a lot of really amazing government sponsors. ”

The Department of Energy (DOE) has also been a key supporter, going back to McDonald’s graduate school research and then through grants that Mosaic was awarded through the DOE’s Small Business Innovation Research (SBIR) program, ARPA-E, and Advanced Manufacturing Office (which also funds Activate fellowships).

“We always recognized that there was something really special about the ability of these materials to get CO2 directly out of the air, and the work we did for the Navy and NASA let us prove that and DOE’s funding allowed us to keep building and improving,” he says.

Then in 2019, Mosaic Materials decided to focus more of its efforts on direct air capture (DAC), which had begun gaining interest and momentum.

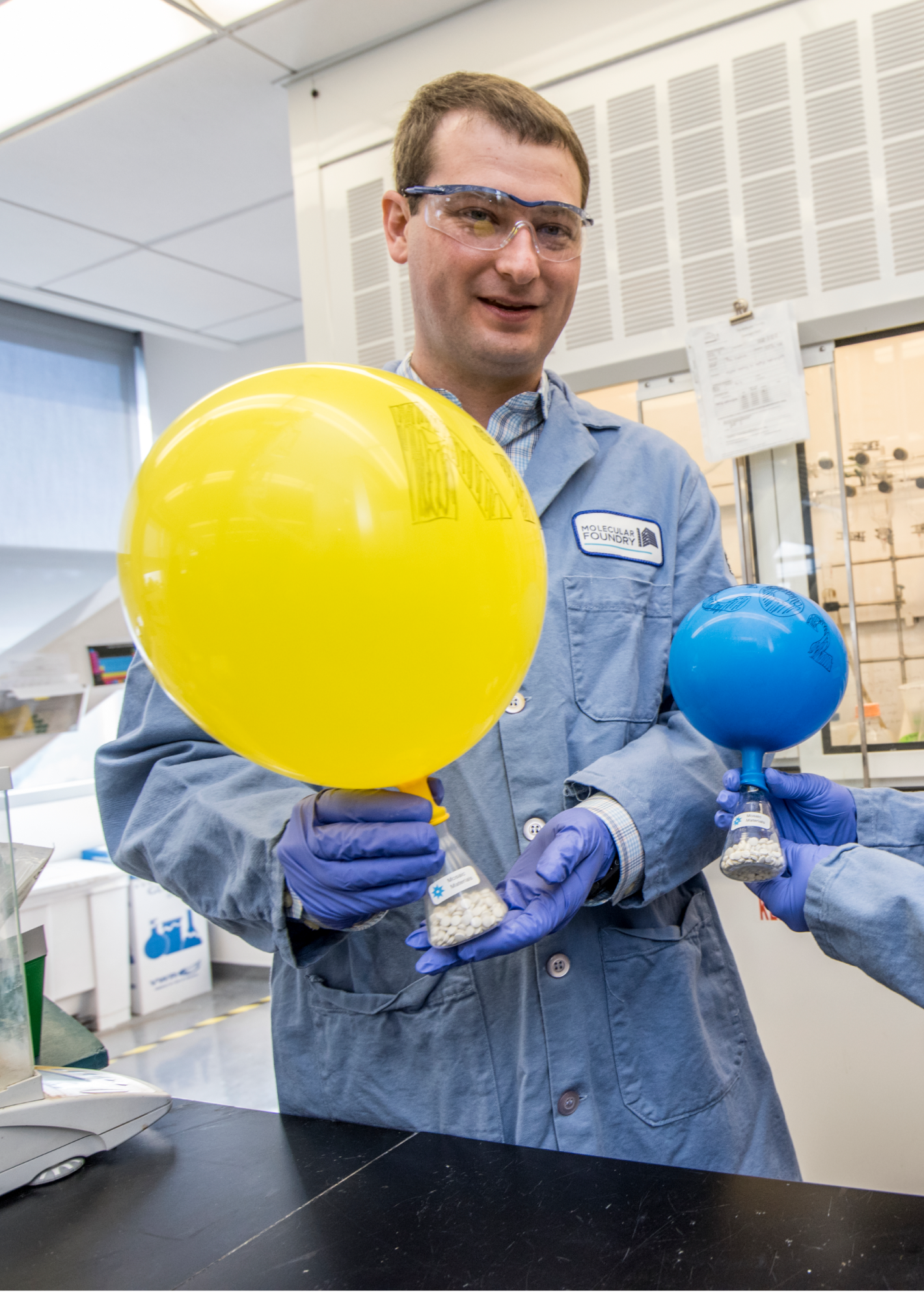

Tom McDonald (Cohort 2015) demonstrating CO2 absorption in 2017.

Soon thereafter, McDonald first connected with Baker Hughes. While it has a long history as an oilfield services provider since its 2017 merger with GE’s Oil & Gas division Baker-Hughes has invested in a range of clean energy technologies including carbon capture.

“Removing carbon through a multi-pronged approach, including direct air capture, is critical to overcoming climate change,” Rod Christie, executive vice president of Turbomachinery & Process Solutions at Baker Hughes, said in a press release.

The company was drawn to the fact that Mosaic’s DAC technology requires significantly less energy to operate and provides a lower total cost of ownership, compared to other solutions, and that it can be used across the energy and industrial value chain, “including refining, aviation, shipping, municipalities, steel, and cement manufacturing.”

McDonald, who has left Mosaic to explore new opportunities, says his team’s dedication and belief, and the support of Mosaic’s partners, funders, and champions, make this inflection point possible. “I will be forever grateful to them,” he says.

Notes:

This is the second acquisition of an Activate Fellow-founded company. Early last year, the European battery manufacturer Northvolt bought Cuberg, a lithium-metal battery company founded by Cohort 2016 fellow Richard Wang.

McDonald’s co-founder Steven Kaye was also a fellow in Cohort 2015. While he took a different path—leaving Mosaic for a material innovation role at Apple and is now CTO of an energy storage company—he has been a key part of Activate’s community, serving on our fellow selection committee among other roles.